|

DURING THE SECOND WORLD WAR |

|

|---|

THE HEMP MILLS WORKERS:

AMERICA’S

FORGOTTEN WAR WORKERS

Unfortunately whenever historians deal with an important era or subjects, they seem to have a tendency to concentrate their attention mostly (if not exclusively) on the major players. The Generals, the Politicians, those who had major roles in decision making etc., and completely ignore, or at best, give token lip-service to what we would think of as the average man or women on the street living through that experience.

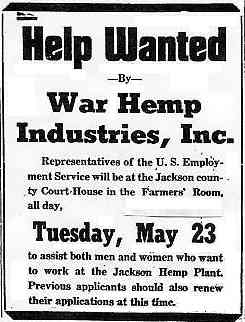

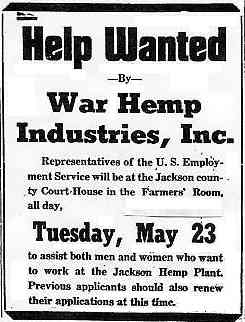

Thus, especially given the censored nature of the subject at hand, historically finding itself planted right in the middle of the Reefer Madness Era. Very little has come down to us about the Hemp factory workers themselves. Those who operated the machines, who transported the hemp from place to place, etc. And so we find ourselves asking; Who were these forgotten war workers (mostly women) who made victory possible?

To some extent old newspaper articles (primarily dealing with plant operations) provide some insight into the workers themselves. The following is a good example, taken from the Iowa, “Mason City Globe Gazette” (June 9, 1944p1). And again, while dealing mostly with the factory operations, it also gives us some insight into the workers themselves.

The Mason City Globe Gazette 1944-06-09p1

80 EMPLOYED IN HEMP PLANT

THEY'RE TURNING OUT FIBER HERE AT RAPID PAGE

"Over Half of Workers Women; Plant Looks Like Threshing Room

They're turning out baled hemp fiber at the War-Hemp industry plant on the south Clear Lake road so fast that you can hardly see them for dust. That's literally true. The main part of the brand-new plant looks like a threshing room. The air is hazy with dust from the hemp, and many of the employees wear makeshift masks over their noses and mouths to keep out the worst of it.

Although the machines have been running only a few days, the big bales of fiber are beginning to pile up in the storage room, ready for Shipping to eastern factories for processing into rope, matting, packing material and all the diversity of products in which hemp, in some form, is fighting the war. The plant is now employing about 80 men, women and girls, but will soon step up its payroll to 120, according to F. A. Cahalan, general manager. At least half of these employees are women and girls, many of them doing what used to be men's work. They seem to love it, too, and the foreman maintains that his "gals" turn out just as much of the finished fiber as the men.

As you drive past the armed guard at the gate to the plant, you see stacks and shocks of the grayish-brown hemp—last year's crop —waiting for processing. There are 8,252 1/2 tons on hand right now. This is the whole hemp stalk, just as it was harvested last fall.

First step in the conversion of the raw hemp into the big bales of finer stacked in the storage room is a drying process. The stalks are pitch-forked on to a platform attached to a slowly-moving conveyor belt which carries them through a drying oven. After a 45-minute baking, the hemp is ready for the breaker. There are 2 breaking machines, side by side in the main room of the plant. These, as well as all the rest of the machinery, are steam-powered, and fuel for the boiler is provided by waste from the processing of the hemp. The breakers crush the dried hemp stalks and toss the fiber, which is the outside covering of the hemp plant, on to T conveyor belts which carry it through another machine where it is untangled.

It comes out at the far end of the room in orderly hanks and is lifted off the belt by a girl who hands it to one of a group waiting in line. These girls are the hacklers, who "comb" the hemp by drawing it over blocks of wood studded with 6-inch spikes. The short strands of fiber are caught among the spikes and the longer strands—the grade A hemp—are then tied into hanks and placed in a large crate ready to be baled.

Several of the workers are in charge of cleaning the short fibers out of the hackles and gathering it into piles which arc then baled separately. This low-grade fiber is used for packing and matting, while the long-fibered hemp makes strong rope.

Much of the machinery in the plant has wooden parts wherever they can be used. The building itself is largely wood, having been built during steel-scarce war times."

|

|

The following article (as per the New York Times, Mar. 27, 1944) is a bit more descriptive. Note the way it hints about the labor shortages cased by the war. Part of which was solved by using (we presume) normally stay at home housewives, some of them working from their own homes, to perform part time work.

So as can be seen, we can learn a lot of bits and pieces about the every day workers through these old newspaper articles.[photo of the home/factory not shown]

New York Times - Mar. 27, 1944 p21

WAR PLANT SET UP IN A QUEENS HOME

Family Produces Grommets Also Employs Six Girls and Forty Housewives in Area

Lining the basement walls of the neat, green-trimmed, gray-shingled house at 139-02 Fourteenth Avenue, College Point, Queens, are huge posters proclaiming: “Victory Begins at Home!” The emphasis seems somewhat unnecessary, for in this case “home” shelters not only William A. Young and his family but his thriving war plant as well.

Six employers, working on machines in two shifts, and forty housewives working by hand at home in their spare time are producing 1,500,000 to 2,000,000 grommets each month. Grommets are small rings of cord or hemp that are used as washers on bolts in naval vessels. Grommets go into submarines, landing craft, “ducks,” barges and sometimes into planes.

For the duration Mr. Young said business will be continued at the house, despite the fact that he has a large factory, now closed, in Whitestone. Fuel and manpower shortages, combined with transportation difficulties, convinced Mr. Young, a little more than a year ago, that production would be simpler at home. “I figure we could heat our living quarters and shop at the same time,” he said. “the plant was a big barn of a place that we could not keep warm enough for the help.”

A FAMILY ENTERPRISE

So far as the Youngs are concerned, grommet manufacturing is a family enterprise, Mr. Young, a former sandhog who has helped build tunnels all over the country, invented the machines on which the washers are made. He boasts that his work is “100 per cent war contracts” and that production is ten times greater than it was in the Whitestone factory.

Motherly, gray-haired Mrs. Young is office manager. In addition she comprises the entire training department, teaching new employers, known to her as “the girls,” how to work the machines, and neighboring housewives how to make grommets by hand. In the odd moments she finds between running the office and her household--and when she is not raising flowers or whipping up a tasty kidney stew---Mrs. Young relaxes in her favorite chair and makes grommets. Sixteen year old Roland is in his third term at the Woodrow Wilson vocational High School, where he is learning to carry on the business. After school and on Saturdays he works for his father--the Youngs answer to the juvenile delinquency problem. Roland invests most of his earnings in War bonds and has about $1,500 worth of them tucked away as a backlog for his higher education.

Another son, William, recently enlisted in the air force. His father explained that, although William had been making more than 50,000 grommets a week, he felt “like a slacker” and joined up, confident that his family would be able to car on.

In the whitewashed basement the hum of busy machinery provides a low accompaniment scarcely heard above the4 sound of the radio, which is kept going all day. “The girls” prefer popular tunes and appear to work in swing rhythm like the music that surrounds them.

An oil burner, tucked away in one corner, is the only hint that this is part of a home. In another corner green-enameled benches and tables form a lunchroom. Coffee and tea can be prepared on the gas stove and meals, carried to work, stored in the small icebox. In pleasant weather according to Mrs. Young, “the girls” have lunch in the yard, where they make use of the hammocks, swings and an outdoor grill.

Miss Mary Van Dam, Mr. Young’s secretary, left a Wall Street job because she wanted to do defense work. Her office is a corner of the sun parlor, where a desk, typewriter and adding machine seem slightly out of place, surrounded as they are by potted plants, overstuffed furniture and family photographs. Miss Van Dam, too, makes grommets by hand “if I have a spare half-hour.”

In fact, there are only three residents of the house who do not manufacture grommets. So far, no one has been able to teach Chubby, the white spitz, Luck, the black French poodle, or Mitzi, the tame, beer-dringk squirrel, how to make them.

Who Was 'HELEN THE HEMPTRES?'

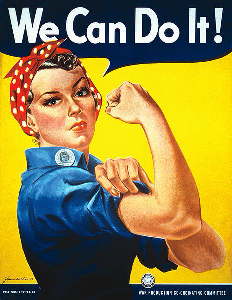

Industries, Rosie the Riveter |

Agricultures, Helen the Hemptress |

Unlike ‘Rosie the Riveter’ (a fictional poster character who came to symbolize all of America’s working women during the war), no such campaign was ever launched around ‘Helen the Hemptress’ (also a fictional character) and probably for good reason. While Rosie became a symbol of Industry, Helen would have been a symbol of agriculture where women were already expected to play an equal role in work. Remember we are dealing with the early 1940’s, a time when many men resented the very idea of a women having an independent job. Some call it the “Don’t worry your pretty little head about economic matters my dear, I will take care of you . . .etc.”, syndrome. Thus, part of the ‘Rosie the Riveter’ campaign was meant to convince males (yeah, the guys) that it was ok for a women to go out and get a job. After all, it was for the war effort, etc.

However, (again) as agricultural women were already expected to perform lots and lots of manual labor on the farm, no such campaign was needed. In addition, unlike ‘Rosie the Riveter,’ ‘Helen the Hemptress’ would have been working in an industry caught right in the middle of a massive hysteria campaign. And no amount of ‘Hemp For Victory” films were going to change the fact that just a few short months earlier, all the talk was about Marihuana the Killer Weed. Hard to go around selling war bonds or do a rah-rah propaganda campaign so someone could go out and grow, “The Assassin of Youth,” if you get the drift.

Thus we are forced to use surrounding circumstances to find out certain things about her.

- First, we know from the (very few) old pictures that we have been able to obtain, that most of the Hemp workers were women, so she would have felt comfortable working with her peers.

- Next, we know from the locations of the Hemp Mills, that Helen would have lived in a rural area. Not necessarily a farmer’s wife, but probably someone already used to hard labor.

- We know that while the pay (by today’s standards) would not have been the greatest, by their standards, it was pretty good. Especially when one considers that we were just coming out of the great depression and that women (back in those days) were not used to getting equal pay for equal work.

- But in any case we can safely presume that patriotism NOT PAY was the main motivating factor that inspired Helen to get a job at her local Hemp Mill.

- We also know that she must have figured out that something was amiss with the Reefer Madness campaign of just a few months ago. After all, here she was working with “the Weed of Madness” yet didn’t see anyone around her jumping out of fifth story windows, etc.

- We also know that after the war (when the Hemp Mills were closed) that like ‘Rosie the Riveter’ she too would have left her job and gone back to her pre-war duties.

AFTERWARDS:

Without a doubt there will be those today who will view these workers as nothing more then a group of Marihuana workers (a.k.a. unwashed hippies). However, as we have seen from various old newspaper/magazine articles (especially given the critical times), maybe ‘Rosy the Riveter,’ style patriotism had more to do with it.

Unfortunately it seems that our country has developed a good case of selected amnesia on the whole subject. Thus, we have no oral records, no historical societies giving praise, not monuments . . . all that we have to go by are old newspaper articles and (unfortunately for us) they are most general in nature. And, granted, there might be some old agricultural war-board records storied away somewhere in one of our national archival libraries. In all probability they will contain nothing more than simply statistics; How many pounds of finished Hemp, produced per worker, etc. Nothing that will shed any light on the subject, thus (at least for now) ‘Helen the Hemptress’ and her sisters as destined to remain unsung hero’s but hero’s never the less.

WANT TO KNOW MORE:

=====================

Due to space / download time considerations, only selected materials are displayed. If you would like to obtain more information, feel free to contact the museum. All our material is available (at cost) on CD-Rom format.

CONTACT PAGE

BACK TO SECTION IV |